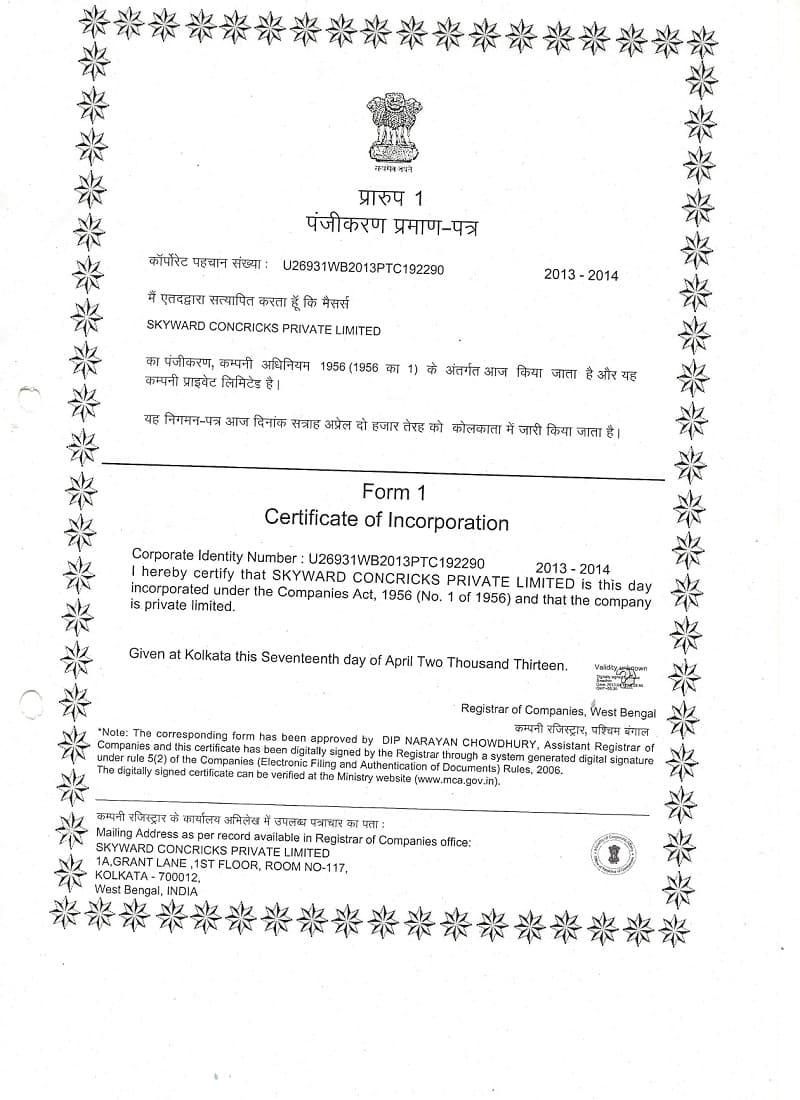

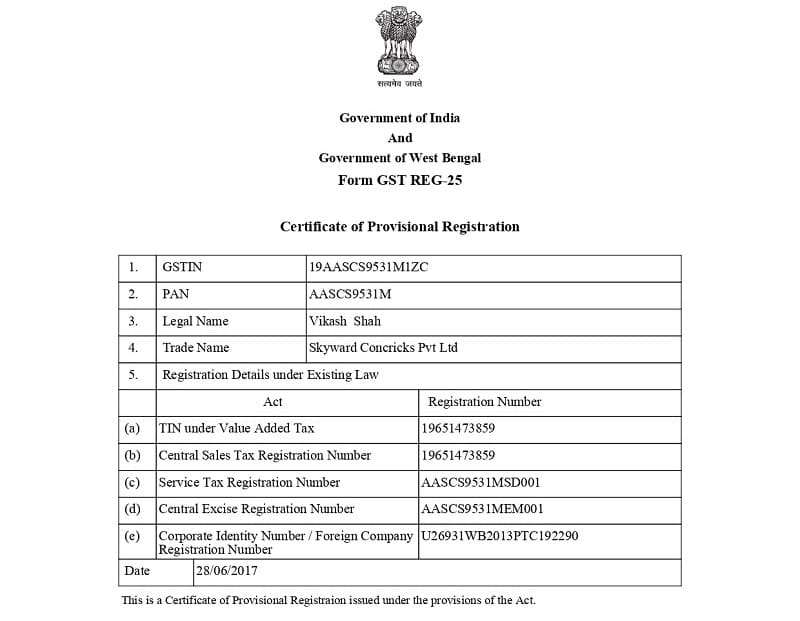

Established in the year 2013, Skyward Concricks Pvt Ltd is an example of ethical business & strong professionalism. Over the years the company has shown its stand in the market through consistent quality product & competitive pricing. Having a long visionary approach the company commenced production of Fly Ash based product. Today Fly Ash based building material is widely accepted by most of the architects & developers in the country. With an integrated R&D system, the company carries an extensive knowledge of Fly Ash- as an alternate green building material. ‘SKY’ is the brand which has been conceived & nurtured by the company and today it’s known by its value in building material industry.

•To be recognized as a Leading Manufacturer of Alternate Green Building Material.

•To manufacture & supply Consistent Quality Fly Ash product

•To maximise Fly Ash content in concrete products.

•To create value for all Customers, Investors & Employees

•To innovate more Green Building Product through continuous R&D

•To create Clean & Healthy Environment.

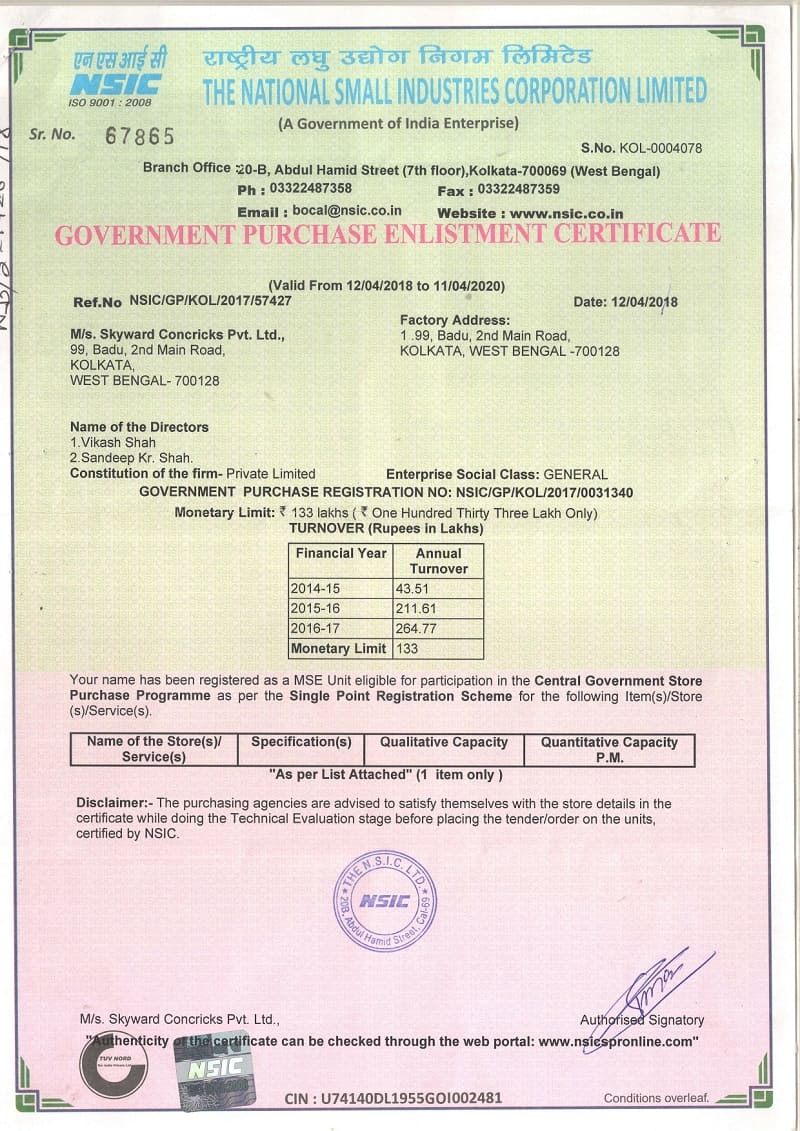

The Company is managed by a team of individuals with diverse background. Each one excel in their respective line and synergizes together towards one common goal. Under the strong leadership of directors having long experience in the field of infrastructure development, the Company has been managed in most systematic and efficient manner. A steady growth in production volume & sales turnover over the years vouch for the same. Every employee in the organization from management level to execution level endeavor to achieve standards set the company. A business may run on experience but a successful business runs on right values which have been perfectly imbibed at every level in the organization. The Company‟s management is divided in three tiers-1. Directors 2. Managers 3. Supervisors

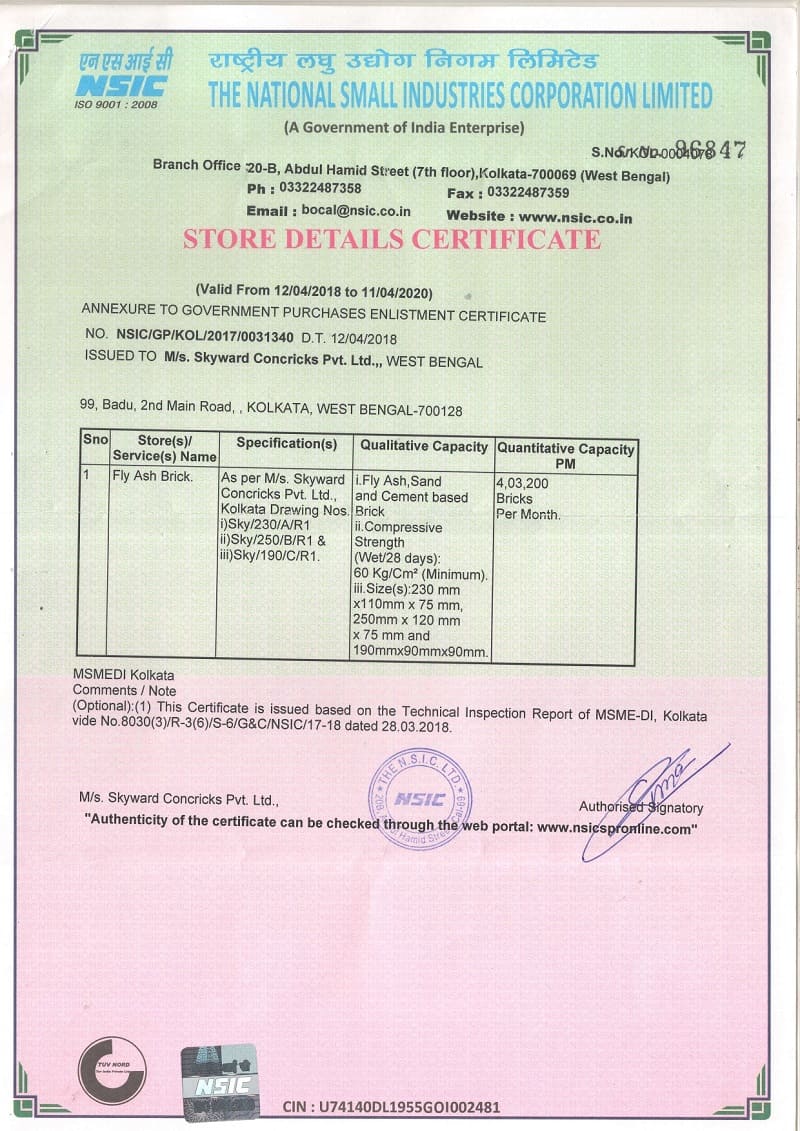

We are one of the few manufacturers in India to have BIS Certification for Fly Ash Brick under IS 16720: 2018. Quality is never compromised to achieve quantity. Quality is monitored & controlled at every stage of production. Starting from raw material to finished product each item is inspect & tested in a fully equipped in house Laboratory. A team of laboratory technicians & supervisors make sure that material mix design & production is done in the manner that the final product meets all the desired standards. Each day’s production constitutes a batch and every batch is distinctively stacked. Samples from each batch are tested at fifteen & twenty eight days. Dispatch is done only after curing is fully complete & required strength is achieved. Each delivery can be tracked easily for its batch & production details. Quality Control Reports are prepared for raw material, production process, curing process, finished product & final dispatch. These reports ensure immediate detection of quality deviation & its correction. This is how quality is assured in the whole process of production.

The manufacturing unit is situated at Barasat, Kolkata spread over an area of 3.33 acres of land with a total covered area of around 20,000 Sq. Ft. Machinery & Pre-curing area covers around 12,000 Sq. Ft. The unit is equipped with fully automatic production line with batching plant for accurate quantity of raw material. All machinery is Indian make & has the ability to work round the clock. The heart of production line- “Hydraulic Press” has a capacity to press at 300 Metric Ton pressure which is enough to produce top grade quality brick. The press runs at a cycle speed of 18 second that can produce 3,000 Bricks per Hour. The production line has an installed capacity to produce 2.88 Cr bricks p.a. Production is ensured along with high safety standards & pollution free environment.