• It can be used for all Load or Non-Load Bearing Structures like Outer Wall, Partition Wall, Boundary Wall, Columns and Foundation

• It can also be used in construction of Water Tank, Septic Tank, Drains, Side Walk, Arches, Elevation and all other places where conventional bricks are used.

• No Special Skilled Worker Required to use Fly Ash Brick. Same conventional method is used for laying Fly Ash Brick.

• No Special Adhesive or Dry-Mix Mortar Required for laying Fly Ash Brick. Regular Cement-Sand mortar is used in the ratio of 1:6 or lesser for laying & plastering.

• No Need to Soak Fly Ash Brick in Water. Only little water sprinkle is sufficient before use.

• Fly Ash Brick can be Half Cut, Quarter Cut, Corner Cut with just hammer as per requirement.

• Plumbing & Electrical Groove Cutting can be easily done using electrical wall chaser or conventional hammer & chisel.

SKY Brick helps to reduce cost of construc tion. Having superior finish & consistent size, reduces the need for plastering & saves plaster cost considerably. Plaster of Paris can be applied directly without cement plaster. Also plasteringcan be avoided if used for compound wall or warehouse.

There are three major environmental benefits:

1. Utilization of hazardous fly ash generated in huge volume by thermal power plants which is oth

erwise dumped in ash ponds & pollutes the environment.

2. Saves precious agricultural top soil by discouraging clay brick which

exploits the clay reserve causing adverse environmental impact on biodiversity & destabilization of

soil structure.

3. Fly Ash Brick manufacturing does not involve in fire curing unlike conventional brick kiln that emits toxicgases from its chimney and pollutes the environment.

Our manufacturing composition & technique ensures high compressive strength. SKY Brick can easily be used for load bearing wall & structures.

Because of its solid compaction under high pressure, there are negligible pores to allow water to pass through. Thus it keeps wall damp proof even in monsoon.

Fly Ash & Sand being more than 90% constituent, it serves as an excellent fire resistant. It can withstand fire for hours depending on wall thickness.

SKY Brick has low thermal conductivity. It keeps home cooler & thereby reduces the use of Air Conditioners and saves substantial energy.

SKY bricks are sound absorbent & restrict sound transmission, keeping inside a peaceful & pleasant environment.

As the material used is all Non Organic, SKY Brick provide great resistance to pest. Also its highly compact structure resist pest to penetrate. Unlike clay bricks which uses mud containing mixture of organic & non organic minerals, thus making more susceptible to pest.

Due to high compressive strength & better chemical bonding between cement & fly ash, breakages are negligible. Even during trans portation & rough handling at site, crack and breakage are substantially low.

Being a concrete in nature, SKY bricks are more durable & long lasting

SKY Brick are casted & pressed in steel moulds giving themthe perfect size & shape.

Sr No. |

Parameters |

Value |

|---|---|---|

| 1 | Composition | Fly Ash, Aggregates, Cement, Admixture |

| 2 | Compressive Strength | Above 75 Kg/cm² ( As per Requirement) |

| 3 | Water Absorption | Below 20% |

| 4 | Density | 1100-2000 Kg/m3 |

| 5 | Size Tolerance | +/- 20mm in Length Width (Taking 10 Bricks), +/- 3mm in Height |

| 6 | Drying Shrinkage | Below 0.05% |

| 7 | Efflorescence | Nil or Negligible |

| 8 | Color | Uniform Grey |

| 9 | Reference IS Code | 16720 - 2018 |

Properties |

SKY - Concrete Brick |

Traditional Red Brick |

|---|---|---|

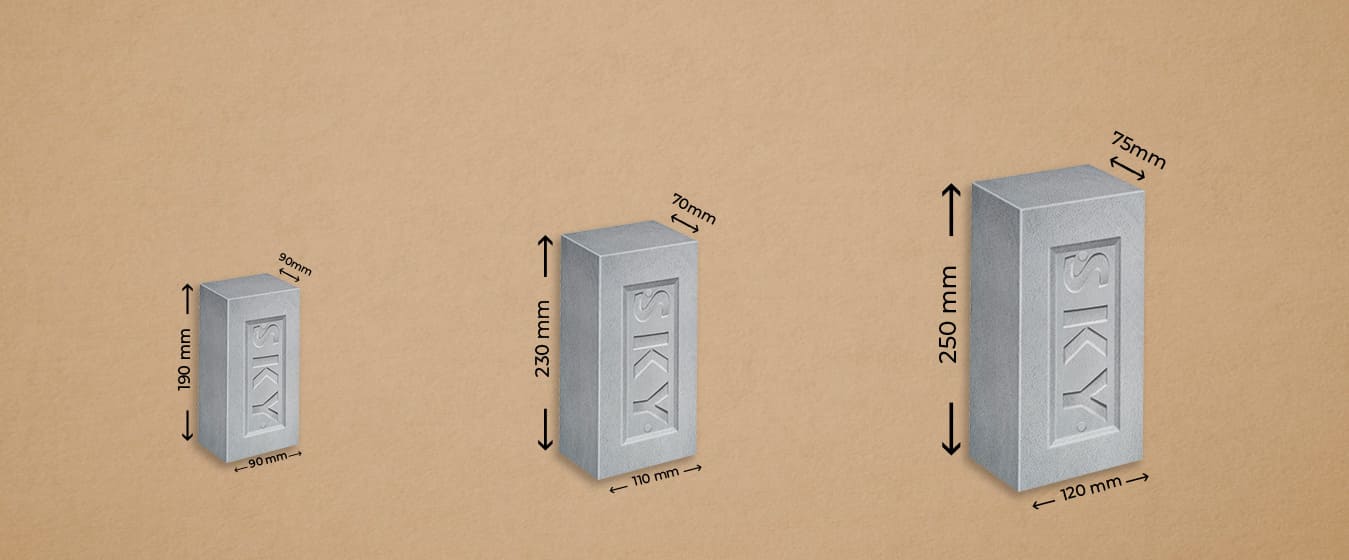

| Sizes | 190x90x90mm 230x110x70mm 250x120x75mm |

10x5x3 Inch |

| Size Variation | Variation +/-2mm | Variation upto 20mm |

| Compressive Strength | 80-120 kg/cm2 | 50-80 kg/cm2 |

| Density | 1300-1800 kg/m3 | 1400-2000 kg/m3 |

| Shape | Perfect Machine Finish | Irregular |

| Quality | Single grade | 4 to 5 grades |

| Transit Breakage | Less than 2% | 2-5% |

| Plastering | Max 1/2" thick | Min 3/4" thick |

| Aging | Gain strength with age | Reduces strength with age |

| Damp Resistance | Water absorption less than 15%(Good damp resistance) | Water absorption 15-25% (High possibility of damp) |

| Fire Resistance | Superior resistance | Low resistance |

| Termite Resistance | No fungus & algae germination due to non organic properties | Algae possibility |

| Sound Insulation | High Insulation | Low Insulation |

| Efflorecence (Nona) | Negligible | Very High |

| Thermal Conductivity | 0.9 w/m2c- Lower TC keeps home cool, saves electricity | 1.25 w/m2c- Higher |

| Air Pollution | Green Category Indusry | Chimney Pollution under Red Category |

| Soil Erosion | Utilizes Polluting Material- Fly Ash | Use agricultural top soil |

| Quality Standard | 16720 Certified | No quality certification |

| Ease of use | No soaking required | Must be soaked before application |

| Application | All masonry work | Same |

1. Buy Fully Cured Fly Ash Brick. Minimum Curing time is 21 Days. Check the Date of Production of the batch from which delivery is being made.

2. Procure bricks from a BIS certified manufacturer and ensure that the manufacturer has a fully equipped laboratory for testing all the specification of Standard Bricks.

3. Seek Material Test Certificate (MTC) from the manufacturer for each batch.

4. If you are a bulk purchaser, ensure that the manufacturer has required production capacity, infrastructure & sufficient stock.

5. Do not buy unbranded bricks. Buy only bricks with manufacturer’s brand mark on it. Quality of bricks is always associated with manufacturer’s Brand.

6. Ensure bricks are made with OPC-53/43 grade cement of reputed make and not PPC or PSC.

7. Ensure bricks are made with Dry Powder Fly Ash and not Pond Ash.